Robots

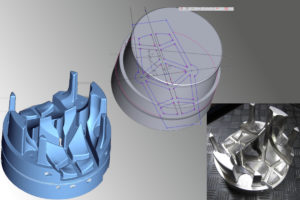

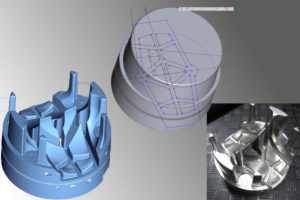

Scan To Reverse Engineer with Functional 3D

Zoom

When a part goes out of production or drawings need updating, 3D scanning can help you speed up your design workflow and meet customer obligations.

It’s a challenge that becomes more common by the day: A smaller manufacturer can no longer get critical parts from their supplier, but drawings don’t exist. How will they continue to meet customer contracts? OR, drawings have changed over the decades but weren’t documented along the way. How long would it take to reverse engineer that key part and get work flowing again?

3D scanning technology offers very real benefits to small and medium-sized manufacturers in a variety of areas, including reverse engineering to solve supply chain challenges or to embrace additive manufacturing. Polaris MEP has teamed up with 3D scanning specialist Christopher Wilczewski for a series of fast-paced webinars about the applications of 3D scanning in manufacturing.

This third and final "episode” in our Spring 2022 series focuses on the potential benefits of 3D scanning for reverse engineering/CAD.

WHAT TO EXPECT

1) Overview of the role 3D scans play in the "new” reverse engineering

2) Understand how you can create Surface CAD bodies to be used in traditional CAD applications – even with organically shaped or hand made objects

3) Hear how 3D scans can allow for modern manufacturing such as Additive / 3D printing or forging

4) Manufacturer Mini-Success Story

WHO SHOULD ATTEND

- Owners, Founders, senior executives of RI manufacturing companies

- Engineering, Maintenance, Procurement leads

- Operations, Production leads

ABOUT THE TRAINER

Christopher Wilczewski is the Founder and CEO of Functional 3D, a 3D scanning service and consulting company based in Providence, RI. The focus of Functional 3D is to bring the value of 3D capture technology without the large upfront costs and time associated with integrating this kind of technology. Industries supported include commercial construction, manufacturing, design and historical preservation with projects as small as a Revolutionary War era flint to as large as a 17-story building in New York City.

Prior to starting his own firm, Christopher was an engineer and account manager at FARO Technologies, one of the leading manufacturers of 3D capture technologies. There he had the opportunity to learn and develop workflows in various fields and organizations across the US igniting his passion for the technology.

Christopher is a member of DesignXRI and the Rhode Island Manufacturing Association.

Innovating for the Future

Zoom

As the largest technology business in Pittsfield, the heart of the Berkshires, General Dynamics is always looking to expand our world-wide supply chain, particularly in Massachusetts. General Dynamics Mission Systems will be hosting an Innovating for the Future event at the Berkshire Innovation Center in Pittsfield, MA. The Berkshires are a key location for General Dynamics Mission Systems and this event is aimed at furthering our relationship with the community through strengthening the local industrial sector.

Due to space limitations, this event is by invitation only. For more information, please contact [email protected]

Offshore Wind Industry: Landing Supply Chain Opportunities For Local Manufacturing

Zoom

The offshore wind industry has arrived in Massachusetts.

Where will the components of the planned offshore wind turbine structures be manufactured? The answer is crucial for local communities and businesses, particularly manufacturers interested to expand into new markets through participation in a diverse supply chain.

Join us to learn more about the burgeoning offshore wind industry and how your company can participate.

Is There Really A Correlation Between Industry 4.0 & Cybersecurity?

Zoom

Join us to learn more about why cybersecurity is foundation to Industry 4.0. A brief introduction to i4.0 will be provided. Our panel will discuss possible cybersecurity risks created when deploying IIoT (Industry Internet of Things) and other ICS (Industrial Control System) devices in industrial network environments. The adoption of i4.0 technologies may require the implementation of more sophisticated network architecture and design. That flat network topology of the past may no longer provide adequate protection of your IP (intellectual property) and sensitive information. It may be time to secure and segment your IT business technology from OT (Operational Technology) / ICS (Industrial Control Systems). Or, you might consider implementing a zero trust security model similar to the one embraced by the DoD earlier this year.

Register now to learn more about these and many other cyber hygiene best practices. Please bring your questions to this webinar as time will set aside for a Q&A session as well.

ISO Internal Auditor Training Session (1132361)

This is a 2-day hybrid training event totaling 8 hours each day*.

Who Should Attend: This course is recommended for anyone involved in designing, implementing, maintaining, and improving a quality management system and/or performing internal audits of a quality management system, such as quality officers, managers, and auditors. No prior knowledge of auditing, quality management systems, or ISO 9001:2008 is required prior to attending this course.

Course Highlights / Topics Covered:

- ISO 9000 terms, definitions, overview

- Seven Quality Management Principles

- ISO 9001 Requirements and Interpretation

- Define what an audit is and the types of audits

- Define qualifications necessary for an internal auditor

- Define the various roles and responsibilities of the internal audit team

- Audit roadmap

- What are internal audits

- Why are internal audits conducted

- What preparatory work should be carried out before an audit

- What to pay attention to during the audit

- What is a good audit report

- What aspects are important in monitoring audit results, corrective and preventive actions

Students will benefit by:

- Learning how to plan, conduct, and report quality audit results

- Enhancing your understanding of the components of an internal quality audit program

- Gaining an in-depth understanding of ISO 9001 requirements

- Getting answers to your toughest audit questions

Capturing a working knowledge of the practices, roles and responsibilities of an auditor.

Costs:

The course is offered on a per seat bases through the Workforce Training Fund Express Grant Opportunity from the Commonwealth Corporation. The cost of the training is $1000/seat; however, through the Express Grant program, if approved, the WTFP will reimburse you for up to 50% of the actual cost of training (for companies 100 employees or more), OR, full reimbursement of the cost of training for companies with 100 employees or less.

Basic Geometric Dimensioning & Tolerancing

WPI/virtual MA, United States

Geometric Dimensioning and Tolerancing is the universally accepted method of communicating dimensioning requirements on engineering drawings. This workshop will help you understand and use this universal engineering language to communicate the types and amounts of the inevitable variation that parts are allowed to have, per the drawing.

Course Description & Outline

Intended for practicing professionals who create drawing specifications or read drawings, this course helps students make sense of a topic that some find overwhelming. In a safe learning environment, the key principles are explained and brought down to the real world. More than simply memorizing symbols, students leave this course with a working understanding of how the system works and feel confident fully understanding drawing requirements and creating their own tolerancing schemes for parts. This course provides lots of practical hands on exercises to drive home the concepts and encourage questions and effective discussions. The exercises go beyond the theory to show how tolerancing works on real working parts.

- Fundamentals of GD&T: Types of variation and how they’re controlled. Features of size and surfaces. Rule #1. Definitions of maximum material condition (MMC) and least material condition (LMC) and how they are used to determine bonus tolerance.

- Tolerances of Form: Controls of flatness, straightness, circularity and cylindricity. Examples on how they are specified, their meaning and principles of verification. Straightness and flatness controls applied to features of size and surfaces.

- Concept of Datums and the Datum Reference Frame: The common point of reference for the part definition from design through manufacturing and inspection. How imperfect parts are measured according to the design intent.

- Tolerances of Orientation: Controls of parallelism, perpendicularity, and angularity applied to surfaces and features of size. Examples on their use and meaning as well as verification principles.

- Tolerances of Location: Controls of position, comparison and conversion from conventional tolerancing. Applications and examples of position used for various features. Composite position tolerances. The classic examples of floating and fixed fasteners will be cited to demonstrate tolerancing for position to avoid interference problems of fit. Projected tolerance zone. Concentricity and symmetry interpretation and application.

- Tolerances of Profile: Controls of profile of a line and profile of a surface. Equally disposed and unequally disposed profile tolerances. Profile tolerances applied to multiple surfaces. Examples of various simple and complex surfaces.

- Tolerances of Runout: Controls of circular runout and total runout.

Learning Outcomes

- Name the four types of variation that exist on parts, recognize the limitations of numeric tolerances and understand the need for geometric tolerances.

- Analyze tolerances expressed numerically and calculate minimum and maximum allowable values for dimensions.

- Understand and apply the symbols used with the geometric system of tolerances.

- Recognize basic dimensions on prints and understand their meaning.

- Identify and properly read feature control frames.

- Recognize when bonus tolerance is available and calculate geometric tolerance values when bonus tolerance applies.

- Create specifications using bonus tolerance where applicable

- Recognize datum feature identifiers applied to features with size and surfaces.

- Identify the datum reference frame including order of precedence.

- Recognize when datum shift is used and calculate the amount of shift.

- Identify and interpret geometric controls on location, orientation, form, profile & runout.

- Construct illustrations of tolerance zones defined by geometric controls, including 3D and 2D tolerance zones,and those allowed to move.

- Properly evaluate inspection data in light of tolerance zones defined by geometric controls.

Who Should Attend

CAD draftspersons, tool designers, technical inspectors, mechanical engineering, technicians, machine shop and tool room supervisors. Design, manufacturing, and project engineers, quality control personnel, engineering managers and supervisors will also find this workshop beneficial.

For More Information on the Certificate Click Here

Virtual Product Launch: CONNEXª Massachusetts

STRENGTHEN YOUR SUPPLY CHAIN & SOURCE LOCAL WITH CONNEXª MASSACHUSETTS

During this virtual product launch, MassMEP, WPI, UMass Lowell, MIT, FORGE, MassRobotics, MassTech Collaborative, AIM & the BIC, known as the Massachusetts Manufacturing Ecosystem, are coming together to celebrate the kickoff for CONNEXª Massachusetts.

CONNEXª Massachusetts is an online marketplace for manufacturers to connect with each other, find local suppliers, discover new business opportunities, and manage their supply chains. The goal of the platform is to increase manufacturing growth among Massachusetts manufacturers as well as help smaller Massachusetts suppliers more easily connect with larger U.S. manufacturers who need their services.

CONNEXª Massachusetts is an online marketplace for manufacturers to connect with each other, find local suppliers, discover new business opportunities, and manage their supply chains. The goal of the platform is to increase manufacturing growth among Massachusetts manufacturers as well as help smaller Massachusetts suppliers more easily connect with larger U.S. manufacturers who need their services.

"The pandemic has delivered a stark lesson on the vulnerability of supply chains,” said Kathie Mahoney, CEO/President of MassMEP. "Disruptions to existing supply chains resulted in shortages of materials and inputs to manufacturing processes, hampering the productivity and profitability of Massachusetts manufacturers and impacting the lives of countless employees and consumers. CONNEXª Massachusetts provides us with a powerful platform to build a strong, Massachusetts-centric manufacturing network that will help local organizations easily identify alternate suppliers; improve supply chain diversity, resiliency, and risk, and expand new business opportunities.”

CONNEXª Massachusetts will allow manufacturers to identify potential suppliers within the state based on their capabilities, not just current production. Results can be filtered to meet a manufacturer’s specific needs based on hundreds of unique criteria, such as equipment, processes, materials, and certifications. In the B2B Exchange Center, manufacturers will also be able to post RFIs and RFQs; qualified suppliers can then respond with their capabilities and availability. These platform features will help Massachusetts manufacturers quickly find the materials and resources they need to meet productivity and profitability objectives, while improving supply chain robustness for downstream manufacturers as well.

Click CONNEXª Massachusetts to join the database today! For more information contact [email protected].

![]()

CONNEX Massachusetts Registration & Training Session

The session is created for Massachusetts Manufacturers that are interested in joining the CONNEX Supply Chain Database. If you are new to the platform MassMEP representatives will be live to get you registered, walk you through the features of the platform, and answer questions.

Session times and dates are listed in the MassMEP workshop calendar. Click the link on your preferred date to join the live session, no registration necessary. Manufacturers will only need to attend one training session.

Through the MassMEP partnership, a lifetime CONNEX Massachusetts subscription is available at no cost for all Massachusetts Manufacturers. To join the CONNEX Marketplace National Database account holders will receive a promotion code that equates to an annual savings of $500/year. This offer is valid through June 13, 2023.