Scan To Reverse Engineer with Functional 3D

<img class="wp-image-24547 size-full aligncenter" src="https://massmep.org/wp-content/uploads/2022/04/Formeinsatz_Reverse-Engineering-300x200-1.jpeg" alt="" width="300" height="200" />

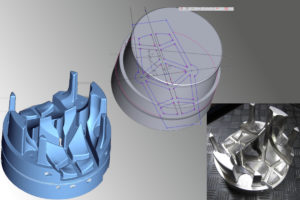

<em>When a part goes out of production or drawings need updating, 3D scanning can help you speed up your design workflow and meet customer obligations.</em>

It’s a challenge that becomes more common by the day: A smaller manufacturer can no longer get critical parts from their supplier, but drawings don’t exist. How will they continue to meet customer contracts? OR, drawings have changed over the decades but weren’t documented along the way. How long would it take to reverse engineer that key part and get work flowing again?

3D scanning technology offers very real benefits to small and medium-sized manufacturers in a variety of areas, including reverse engineering to solve supply chain challenges or to embrace additive manufacturing. Polaris MEP has teamed up with 3D scanning specialist Christopher Wilczewski for a series of fast-paced webinars about the applications of 3D scanning in manufacturing.

This third and final "episode” in our Spring 2022 series focuses on the potential benefits of 3D scanning for reverse engineering/CAD.

<h3>WHAT TO EXPECT</h3>

1) Overview of the role 3D scans play in the "new” reverse engineering

2) Understand how you can create Surface CAD bodies to be used in traditional CAD applications – even with organically shaped or hand made objects

3) Hear how 3D scans can allow for modern manufacturing such as Additive / 3D printing or forging

4) Manufacturer Mini-Success Story

<h3>WHO SHOULD ATTEND</h3>

<ul>

<li>Owners, Founders, senior executives of RI manufacturing companies</li>

<li>Engineering, Maintenance, Procurement leads</li>

<li>Operations, Production leads</li>

</ul>

<h4>ABOUT THE TRAINER</h4>

<img class="size-full wp-image-24540 alignright" src="https://massmep.org/wp-content/uploads/2022/04/headshot12-1-2021-293x300-1.png" alt="" width="293" height="300" />

Christopher Wilczewski is the Founder and CEO of Functional 3D, a 3D scanning service and consulting company based in Providence, RI. The focus of Functional 3D is to bring the value of 3D capture technology without the large upfront costs and time associated with integrating this kind of technology. Industries supported include commercial construction, manufacturing, design and historical preservation with projects as small as a Revolutionary War era flint to as large as a 17-story building in New York City.

Prior to starting his own firm, Christopher was an engineer and account manager at FARO Technologies, one of the leading manufacturers of 3D capture technologies. There he had the opportunity to learn and develop workflows in various fields and organizations across the US igniting his passion for the technology.

Christopher is a member of DesignXRI and the Rhode Island Manufacturing Association.

[mep_register url="https://polarismep.org/event/scan-to-reverse-engineer-with-functional-3d/"]