Manufacturing @ MIT: 2022 and Beyond

Massachusetts Institute of Technology, Walker Memorial 142 Memorial Drive, Cambridge

Hear from top thinkers from industry, government, and academia on manufacturing including MIT professors Suzanne Berger, Duane Boning, Richard Braatz, Josephine Carstensen, Zachary Cordero, Dave Hardt, John Hart, Lionel Kimerling, David Mindell, Yet-Ming Chiang, Elsa Olivetti, Julie Shah, and more.

Over many decades, MIT faculty and researchers have made tremendous contributions to manufacturing technology in areas like CNC machining, 3D printing, and production of pharmaceuticals, as well as on the policy front, with path-breaking studies including Made in America and Production in the Innovation Economy.

By embracing new technologies and a new mindset, manufacturing can play a key role in strengthening our economy, reducing carbon emissions, and improving economic mobility and workforce diversity. Investments in digital production, robotics, photonics, and other advanced technologies will transform products and factory floors, improving performance and sustainability and creating new, well-paying jobs. Many manufacturers operate on paper-thin margins, and workers turn away from jobs they associate with America’s rust-belt decline. Therefore, we must chart a path toward a new, technologically driven, agile, and resilient advanced manufacturing future.

Moreover, with recent lessons about the fragility of our manufacturing supply chains, the federal government is more focused on America’s manufacturing future than it has been in decades. Several top universities have established manufacturing centers to be part of the solution. They are pulling in engineers along with political scientists, economists, and workforce experts, and building deep partnerships with industry and the public sector.

We are excited to invite you Friday May 6, to a symposium that brings together the many people across the institute who care deeply about manufacturing. We will ask what the future might be, and how MIT can make the strongest impact. Please spread the word to your colleagues, students, and research staff.

Please register no later than Friday, April 29, 2022. Lunch and refreshments will be served.

Please use this code for 25% off at registration - Code MFG25

Parking and Accommodation

MIT on-site parking is not available for individuals who do not already have parking rights to lots and facilities on the MIT campus.

Public parking lots, garages, and metered street parking are available in relative proximity to the Walker Memorial building. A list of public parking options can be found here. For ease of transportation, public transportation or ride-sharing is recommended.

For any guests seeking accommodation, a list of area hotels are provided here. For MIT "Preferred Hotels," a discounted rate may be available; please inquire with the hotel directly when making your reservation.

ISO Internal Auditor Training Session (1132361)

ISO Internal Auditor Training May 11th & 12th

ISO Internal Auditor Training May 11th & 12th

This is a 2-day hybrid training event totaling 8 hours each day*.

Who Should Attend: This course is recommended for anyone involved in designing, implementing, maintaining, and improving a quality management system and/or performing internal audits of a quality management system, such as quality officers, managers, and auditors. No prior knowledge of auditing, quality management systems, or ISO 9001:2008 is required prior to attending this course.

Course Highlights / Topics Covered:

- ISO 9000 terms, definitions, overview

- Seven Quality Management Principles

- ISO 9001 Requirements and Interpretation

- Define what an audit is and the types of audits

- Define qualifications necessary for an internal auditor

- Define the various roles and responsibilities of the internal audit team

- Audit roadmap

- What are internal audits

- Why are internal audits conducted

- What preparatory work should be carried out before an audit

- What to pay attention to during the audit

- What is a good audit report

- What aspects are important in monitoring audit results, corrective and preventive actions

Students will benefit by:

- Learning how to plan, conduct, and report quality audit results

- Enhancing your understanding of the components of an internal quality audit program

- Gaining an in-depth understanding of ISO 9001 requirements

- Getting answers to your toughest audit questions

Capturing a working knowledge of the practices, roles and responsibilities of an auditor.

Registration for this event is closed. If you would like more information on how to attend a future ISO Internal Auditor Training, please contact Hayley Steele, [email protected].

MMAP Information Session

Zoom

Massachusetts Technology Collaborative ("Mass Tech Collaborative” or "MassTech”), on behalf of the Center for Advanced Manufacturing ("CAM") is issuing this Request for Proposals for state cost share to support manufacturing projects (Solicitation No.2022-CAM-03) (the "Solicitation” or "Solicitation”) from qualified manufacturers ("Respondents”) located within the Commonwealth’s borders, as part of the state’s on-going commitment to the manufacturing industry. Respondents will be competing against each other for funds dedicated to manufacturing expansion grants to accelerate company growth. The submissions of all Respondents shall be compared and evaluated pursuant to the evaluation criteria set forth in this Solicitation.

The Massachusetts Manufacturing Accelerate Program ("MMAP”) provides capital cost share up to $250,000 for projects located within the Commonwealth’s borders, as part of the state’s on-going commitment to the manufacturing industry.

The program aims to help Massachusetts-based small to medium sized manufacturers prepare their businesses to meet the demands of Industry 4.0 and the manufacturing of new technologies and innovations that align with key industries in the Commonwealth, including semiconductor, defense and aerospace, battery technologies and additive manufacturing.

The MMAP program:

- Provides CAPITAL: Through necessary capital equipment purchases, a manufacturer will have access to new supply chain connections, new opportunities, and growth.

- Creates PARTNERSHIPS: This program aims to make connections between manufacturers and non-profit partners to help build an ecosystem of support for our manufacturers to collaborate and rely on. These partnerships will provide assistance through technical support, workforce development support, business connections, or other means of assistance, depending on the partner, to help manufacturers drive efficiencies and scale their business.

It is a requirement that a company collaborate with a non-profit, academic or quasi state agency partner to receive funding. Non-profit partners include academic institutions of higher learning (except for state academic institutions), or a non-profit such as Mass Robotics, MassHire workforce boards, or MassMEP, or other quasi state agencies.

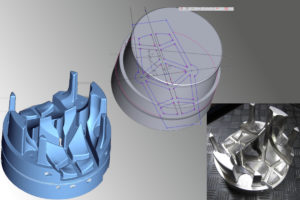

Scan To Quality Reporting with Functional 3D

Zoom

Measurement is the first step in quality control, the foundation of improvement and critical to Customer satisfaction. How can 3D scanning technology improve your quality reporting?

3D offers very real benefits to small and medium-sized manufacturers in a variety of areas. Polaris MEP has teamed up with 3D scanning specialist Christopher Wilczewski for a series of fast-paced webinars about the applications of 3D scanning in manufacturing.

This second "episode” in our Spring 2022 series focuses on the potential benefits of 3D scanning as it relates to quality. Attendees will learn how 3D scans could improve the quality reports provided to customers, increasing satisfaction.

The technology also can be used to confirm that the parts you receive from your suppliers meet your expectations – or even modify them to fit your needs. For example, are you struggling with a plastic part and can’t figure out why? A 3D scan could help you spot deformations AND the data can be used to modify molds to produce the correct shape.

WHAT TO EXPECT

1) Overview of the advantages of 3D scanning for measurement vs. manual quality

2) Best practices / lessons learned for leveraging 3D scans to improve quality reporting and/or automating GD&T reports

3) Insights on how the technology can be used to improve quality of parts received from suppliers

4) Manufacturer Mini-Success Story

WHO SHOULD ATTEND

- Owners, Founders, senior executives of RI manufacturing companies

- Engineering, Quality leads

ABOUT THE TRAINER

Christopher Wilczewski is the Founder and CEO of Functional 3D, a 3D scanning service and consulting company based in Providence, RI. The focus of Functional 3D is to bring the value of 3D capture technology without the large upfront costs and time associated with integrating this kind of technology. Industries supported include commercial construction, manufacturing, design and historical preservation with projects as small as a Revolutionary War era flint to as large as a 17-story building in New York City.

Prior to starting his own firm, Christopher was an engineer and account manager at FARO Technologies, one of the leading manufacturers of 3D capture technologies. There he had the opportunity to learn and develop workflows in various fields and organizations across the US igniting his passion for the technology.

Christopher is a member of DesignXRI and the Rhode Island Manufacturing Association.

Massachusetts Manufacturers At Your Request – Agile and DFM

The past two years have taught us the endurance and tenacity of Manufacturing in MA. As part of that, the top two subjects Massachusetts manufacturers are looking for more insight with hands on training are, Agile & DFM. MassMEP offers a two part module workshop designed for the Massachusetts Manufacturing Industry.

Module one of the series: This course delivers insights into the people, process, tools and metric techniques that are widely utilized withAgile operating models. Trainees will learn foundational Scrum knowledge empowering them to execute plans for incorporating Agile practices and techniques into their own organization. This course is a starting point for the trainee to acquire the techniques, skills, and tools that enable them to build Agile disciplines.

Please note this is One Module that is a two-day training module for each topic. That being written, this workshop requires both days in both modules are to be completed for the full training package. As an attendee you will need to schedule time to attend the training over the four day, eight-hour training time. Example: I will be in training for Agile, May 19th & 26th and in training for DFM, June 9th & 16th.

Please note that it is strongly recommended that you participate in both of these modules to receive the full package of the training.

Manufacturing Your Future I4.0

Industry 4.0 "is a journey of continued improvement & innovation through advanced technologies, process enhancements and integrated information that provides manufacturing companies a competitive advantage.” -Tom Andrellos

This event is for Massachusetts Manufacturers to come together and take a deep dive through the components of Industry 4.0, a view of SMART Manufacturing, and key takeaways on the importance of building a roadmap in I4.0 to remain competitive and see direct impacts to the bottom line.

Subject Matter Experts will be speaking to I4.0 Roadmapping, IIoT, Automation, Additive, CyberSecurity, and so much more. Expect to see these subject matter experts speaking and exhibiting along with other experts in this field at the event.

Join us in-person at the DCU Club inside Polar Park at the WooSox Stadium. Click on the link to register today!

Massachusetts Manufacturers At Your Request – Agile and DFM

The past two years have taught us the endurance and tenacity of Manufacturing in MA. As part of that, the top two subjects Massachusetts manufacturers are looking for more insight with hands on training are, Agile & DFM. MassMEP offers a two part module workshop designed for the Massachusetts Manufacturing Industry.

Module one of the series: This course delivers insights into the people, process, tools and metric techniques that are widely utilized withAgile operating models. Trainees will learn foundational Scrum knowledge empowering them to execute plans for incorporating Agile practices and techniques into their own organization. This course is a starting point for the trainee to acquire the techniques, skills, and tools that enable them to build Agile disciplines.

Please note this is One Module that is a two-day training module for each topic. That being written, this workshop requires both days in both modules are to be completed for the full training package. As an attendee you will need to schedule time to attend the training over the four day, eight-hour training time. Example: I will be in training for Agile, May 19th & 26th and in training for DFM, June 9th & 16th.

Please note that it is strongly recommended that you participate in both of these modules to receive the full package of the training.

Massachusetts Manufacturers At Your Request – Agile and DFM: Module 2

The past two years have taught us the endurance and tenacity of Manufacturing in MA. As part of that, the top two subjects Massachusetts manufacturers are looking for more insight with hands on training are, Agile & DFM. MassMEP offers a two part module workshop designed for the Massachusetts Manufacturing Industry.

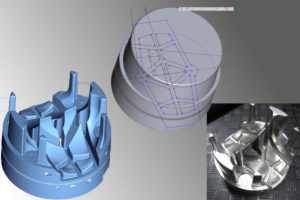

Module two of the series: Design for Manufacturability, DFM, the benefits of different manufacturing processes and the effect of cost based on the manufacturing process and tooling consideration. The Value Engineering Methodology evaluates the different manufacturing processes, tooling consideration and labor content to establish overall cost to decide on the most economical overall price.

Please note this is One Module that is a two-day training module for each topic. That being written, this workshop requires both days in both modules are to be completed for the full training package. As an attendee you will need to schedule time to attend the training over the four day, eight-hour training time. Example: I will be in training for Agile, May 19th & 26th and in training for DFM, June 9th & 16th.

Please note that it is strongly recommended that you participate in both of these modules to receive the full package of the training.

Human Capital Barometrics Information Session

Zoom

Human Capital Barometrics, not a college science class!

Introducing a new tool for workforce information - Human Capital Barometrics.

Why do YOU want HCB?

It can be used to measure your current conditions and help you plan for the future.

What are the benefits?

This can improve hiring, retention, and help you make future investments.

With speakers from both Polaris MEP and VMEC speaking on their own experiences implementing HCB, this is open to all manufacturers in MA, RI, and VT.

Join us for an hour of the who, what, where, when and why of HCB and how it will work in your organization.

Partners:

Scan To Reverse Engineer with Functional 3D

Zoom

When a part goes out of production or drawings need updating, 3D scanning can help you speed up your design workflow and meet customer obligations.

It’s a challenge that becomes more common by the day: A smaller manufacturer can no longer get critical parts from their supplier, but drawings don’t exist. How will they continue to meet customer contracts? OR, drawings have changed over the decades but weren’t documented along the way. How long would it take to reverse engineer that key part and get work flowing again?

3D scanning technology offers very real benefits to small and medium-sized manufacturers in a variety of areas, including reverse engineering to solve supply chain challenges or to embrace additive manufacturing. Polaris MEP has teamed up with 3D scanning specialist Christopher Wilczewski for a series of fast-paced webinars about the applications of 3D scanning in manufacturing.

This third and final "episode” in our Spring 2022 series focuses on the potential benefits of 3D scanning for reverse engineering/CAD.

WHAT TO EXPECT

1) Overview of the role 3D scans play in the "new” reverse engineering

2) Understand how you can create Surface CAD bodies to be used in traditional CAD applications – even with organically shaped or hand made objects

3) Hear how 3D scans can allow for modern manufacturing such as Additive / 3D printing or forging

4) Manufacturer Mini-Success Story

WHO SHOULD ATTEND

- Owners, Founders, senior executives of RI manufacturing companies

- Engineering, Maintenance, Procurement leads

- Operations, Production leads

ABOUT THE TRAINER

Christopher Wilczewski is the Founder and CEO of Functional 3D, a 3D scanning service and consulting company based in Providence, RI. The focus of Functional 3D is to bring the value of 3D capture technology without the large upfront costs and time associated with integrating this kind of technology. Industries supported include commercial construction, manufacturing, design and historical preservation with projects as small as a Revolutionary War era flint to as large as a 17-story building in New York City.

Prior to starting his own firm, Christopher was an engineer and account manager at FARO Technologies, one of the leading manufacturers of 3D capture technologies. There he had the opportunity to learn and develop workflows in various fields and organizations across the US igniting his passion for the technology.

Christopher is a member of DesignXRI and the Rhode Island Manufacturing Association.

Countdown to CMMC Compliance

Zoom

CMMC is less than a year away from becoming a rule. On June 24th, organizations in the defense industrial base (DIB) will have the chance to get guidance and clarity from top DoD officials on program timelines and their responsibility to comply with CMMC and DFARS 7012.

Join PreVeil and some of the nation’s largest Manufacturing Extension Partnerships (MEPs) as they host an important conversation with top DoD officials Mr David McKeown (DoD CISO) and Ms Stacy Bostjanick (CMMC,Director). These speakers will provide guidance on:

- Important CMMC program updates

- Expected changes to program timelines

- Contractor obligations under DFARS 7012

By attending this webinar, DIB organizations will understand changes to the CMMC program, how they can best prepare themselves and the importance of getting their compliance programs started. Sign up today and reserve your seat.

Innovating for the Future

Zoom

As the largest technology business in Pittsfield, the heart of the Berkshires, General Dynamics is always looking to expand our world-wide supply chain, particularly in Massachusetts. General Dynamics Mission Systems will be hosting an Innovating for the Future event at the Berkshire Innovation Center in Pittsfield, MA. The Berkshires are a key location for General Dynamics Mission Systems and this event is aimed at furthering our relationship with the community through strengthening the local industrial sector.

Due to space limitations, this event is by invitation only. For more information, please contact [email protected]