Manufacturing

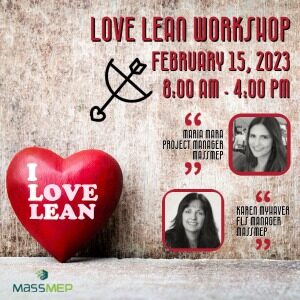

Love Lean Workshop

Love Lean Workshop

As we begin another journey into another new year, we ask, "Where are you on your journey through continuous improvement?" Join us for this one-day workshop in Lean 101 for all levels, if you are new to lean or experienced, as they may spark new lean ideas. This is a touch, see, do workshop!

In this Workshop:

Participants will learn how to use continuous improvement in a hypothetical work environment.

Who Should Attend:

Anyone! This is a basic lean perspective, and this workshop will allow anyone with experience to use as a refresher or for someone new to lean/continuous improvement an opportunity to touch, feel and do while working with lean at any level within your organization.

Cost Of Workshop:

This one-day workshop totals $99. Please be on the lookout for coupon codes on MassMEP Social (LinkedIn, FaceBook, Twitter, Instagram).

Location:

MassMEP

27A Midstate Drive Auburn, MA 01501 Suite 200

508-831-7020

Worcester Chamber of Commerce Manufacturing Roundtable with MassMEP’s Kathie Mahoney

For the first Manufacturing Roundtable of 2023, please join the Chamber in welcoming Kathie Mahoney, President of the Massachusetts Manufacturing Extension Partnership (MassMEP). MassMEP is a nonprofit headquartered in Central Massachusetts, dedicated to providing manufacturers with best practices in workforce, operations, and growth. In total, MassMEP has helped create and retain 17,000 jobs and supported $2.1 billion in growth for Massachusetts manufacturers.

Mahoney started her career at MassMEP in 1999, left for a position at the Rhode Island MEP in 2017, and returned as MassMEP President in 2022. She is recognized as a next-generation leader among her peers in the National MEP Network, and brings years of manufacturing excellence and experience to Massachusetts manufacturers.

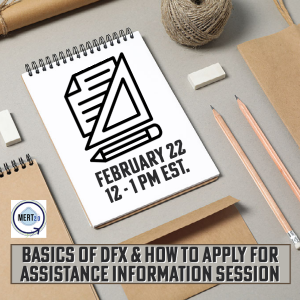

Opportunity for Grant Funded Design Firm Assistance

Are you looking for an opportunity to maximize your new product design prior to production? Look no further!

This informational session is on the Basics of Design for Excellence (DFX) to learn how to apply for the chance to receive $5,000 of expert DFX support from Bayard Design.

Up to 5 submissions will be selected!

Zoom Session: Basics of DFX & How to Apply for Assistance

February 22 @ 12:00- 1:00 pm EST

This program is funded by the EDA Manufacturing Emergency Response Team (MERT) 2.0 grant.

Click the button to send an email to register for the zoom link, or to ask questions.

Central Manufacturing Talent Pipeline Summit

Central Manufacturing Talent Pipeline Summit

Bringing together state funders and employers to learn about current trainings and create strategic plans to meet your talent needs. This free summit will focus on available employer grant funding, workforce training resources and information regarding access to highly qualified manufacturing training graduates in 2023. Networking breakfast will begin at 7:30 AM.

Keynote Speakers:

- Representative Jeffery Roy, House Chair of the Manufacturing Caucus

- Christine Nola, Director of the Center for Advanced Manufacturing at Massachusetts Technology Collaborative.

Join us, Thursday, March 16th at the College of Holy Cross Hogan Conference Center From 8:00 AM - 10:30 AM

Basic Geometric Dimensioning & Tolerancing

WPI/virtual MA, United States

Geometric Dimensioning and Tolerancing is the universally accepted method of communicating dimensioning requirements on engineering drawings. This workshop will help you understand and use this universal engineering language to communicate the types and amounts of the inevitable variation that parts are allowed to have, per the drawing.

Course Description & Outline

Intended for practicing professionals who create drawing specifications or read drawings, this course helps students make sense of a topic that some find overwhelming. In a safe learning environment, the key principles are explained and brought down to the real world. More than simply memorizing symbols, students leave this course with a working understanding of how the system works and feel confident fully understanding drawing requirements and creating their own tolerancing schemes for parts. This course provides lots of practical hands on exercises to drive home the concepts and encourage questions and effective discussions. The exercises go beyond the theory to show how tolerancing works on real working parts.

- Fundamentals of GD&T: Types of variation and how they’re controlled. Features of size and surfaces. Rule #1. Definitions of maximum material condition (MMC) and least material condition (LMC) and how they are used to determine bonus tolerance.

- Tolerances of Form: Controls of flatness, straightness, circularity and cylindricity. Examples on how they are specified, their meaning and principles of verification. Straightness and flatness controls applied to features of size and surfaces.

- Concept of Datums and the Datum Reference Frame: The common point of reference for the part definition from design through manufacturing and inspection. How imperfect parts are measured according to the design intent.

- Tolerances of Orientation: Controls of parallelism, perpendicularity, and angularity applied to surfaces and features of size. Examples on their use and meaning as well as verification principles.

- Tolerances of Location: Controls of position, comparison and conversion from conventional tolerancing. Applications and examples of position used for various features. Composite position tolerances. The classic examples of floating and fixed fasteners will be cited to demonstrate tolerancing for position to avoid interference problems of fit. Projected tolerance zone. Concentricity and symmetry interpretation and application.

- Tolerances of Profile: Controls of profile of a line and profile of a surface. Equally disposed and unequally disposed profile tolerances. Profile tolerances applied to multiple surfaces. Examples of various simple and complex surfaces.

- Tolerances of Runout: Controls of circular runout and total runout.

Learning Outcomes

- Name the four types of variation that exist on parts, recognize the limitations of numeric tolerances and understand the need for geometric tolerances.

- Analyze tolerances expressed numerically and calculate minimum and maximum allowable values for dimensions.

- Understand and apply the symbols used with the geometric system of tolerances.

- Recognize basic dimensions on prints and understand their meaning.

- Identify and properly read feature control frames.

- Recognize when bonus tolerance is available and calculate geometric tolerance values when bonus tolerance applies.

- Create specifications using bonus tolerance where applicable

- Recognize datum feature identifiers applied to features with size and surfaces.

- Identify the datum reference frame including order of precedence.

- Recognize when datum shift is used and calculate the amount of shift.

- Identify and interpret geometric controls on location, orientation, form, profile & runout.

- Construct illustrations of tolerance zones defined by geometric controls, including 3D and 2D tolerance zones,and those allowed to move.

- Properly evaluate inspection data in light of tolerance zones defined by geometric controls.

Who Should Attend

CAD draftspersons, tool designers, technical inspectors, mechanical engineering, technicians, machine shop and tool room supervisors. Design, manufacturing, and project engineers, quality control personnel, engineering managers and supervisors will also find this workshop beneficial.

For More Information on the Certificate Click Here

Advanced Geometric Dimensioning & Tolerancing

WPI/virtual MA, United StatesEven with an understanding of the fundamentals of GD&T, many professionals still lack the confidence to expertly and deliberately apply geometric tolerancing and perform tolerance stack-up analyses to clearly define their product designs. Like with any language, this deeper understanding is built off the fundamentals.

Program Logistics

- On-Site Delivery: 2 Days (16 Hours)

- Online Delivery: 4x 3.5-hour sessions (14 hours synchronous instruction + asynchronous pre-work / homework)

- Cost: $1,399

- CEUs: 1.4

- Modes of Teaching and Learning: Lecture/discussion, Individual work sessions, Group work sessions, Large print review

- Textbook: GeoTol Pro 2020, TCI

- Workbook (additional for virtual): Advanced GD&T Workbook, WPI

- Instructor: Charles A. GIllis, P.E. (bio)

Course Description & Outline

The Advanced course helps students apply GD&T to achieve the mating and functional requirements of their parts. This course reinforces fundamentals and provides applications-based exercises where students apply what they have learned. Applications exercises and calculations are performed individually and in teams. The use of functional dimensioning and tolerancing schemes and its effect on assemblies is emphasized throughout the course. Students will expand their understanding of the implications of their specifications on function, manufacturing, inspection, and quality. Students are introduced to tolerance stack-ups and how variation accumulates through an assembly. Students will gain experience and confidence selecting the product definition strategy for an assembly by working more advanced application examples with their peers under the guidance of an expert in a classroom setting.

- Basic GD&T Review: Variation and tolerance, drawing requirements, variation in perspective, 3D & Standards for interpretation. Engineering product definition & downstream processes, Bonus Tolerance, Rule #1, exceptions & overrides. Ambiguity, types of variation & tolerances, Unrelated & related AMEs. Unrelated & related MMEs. Datums and degrees of freedom. Establishing datum reference frames including datum feature precedence and datum modifiers. Additional datum applications including secondary datum feature at MMB, tertiary datum feature at MMB, calculating allowable datum feature shift, and applications for datum feature modifiers.

- Advanced Datum Reference Frame Concepts: Moveable datum targets, Two holes as datum feature, Hole and slot as datum feature, coaxial holes as a datum feature, rotational control, simultaneous requirements, customized datum reference frame. Applications and establishment of the correct functional datum reference frame.

- Tolerance Stack-Ups: Geometric controls in tolerance analysis, the tolerance stack-up chain, preliminary tolerance assignment, analysis and assignment methods.

- Profile Control Concepts: Review of profile including composite profile. Advanced concepts such as free state variation, non-rigid parts; non-uniform profile, dynamic profile. Profile verification applications & gage design. Accumulation of variation across profile tolerances.

- Position Control Concepts: Review of composite tolerancing and dual segment position tolerancing, Advanced concepts such as cylindrical tolerance zone, rectangular tolerance zone, spherical tolerance zone, conical tolerance zone, position boundary. Position verification application exercises & gage design. Determining the correct position tolerance.

- Boundaries: Boundaries and their applications in design and tolerance analysis. Determining Inner & outer boundaries for features with and without modifiers using various datum reference frames. Comparison among circular runout, total runout, position, and profile for coaxial control. Applications of various coaxial tolerances. Accumulation of variation between coaxial features.

Learning Outcomes

- Construct the appropriate functional datum reference frames for parts after analyzing the mating requirements.

- Apply datum feature modifiers where appropriate based on analyzing the requirements.

- Specify datum reference frames properly to represent the part's functional requirements, including the use and interpretation of datum shift where appropriate.

- Apply geometric tolerancing to control features and ensure mating requirements are met.

- Combine the effects of different types of variation using the concept of boundaries, calculate boundary sizes and use boundaries properly in stack-up analysis.

- Specify tolerances to ensure multiple mating part relationships between constrained features.

- Perform tolerance stack-up analysis to assign critical tolerances.

- Apply geometric controls and symbols properly to suit the functional requirements.

- Calculate linear, axial and orientation stack-ups using parts toleranced with either numeric or geometric tolerancing

Who Should Attend

Design, manufacturing, and quality engineers and engineering technicians will find this workshop beneficial. Anyone involved with drawing review and anyone looking for a deeper understanding of how to apply geometric tolerancing and perform tolerance analysis will benefit from this course.

Prerequisites & Preparations

At least one Basic GD&T workshop/course is required as a prerequisite. It's essential that individuals understand the underlying principles that the Basic course is focused on teaching. In addition, students should have at least 1 year of on-the-job experience applying GD&T in the development of mechanical specifications.

Basic Geometric Dimensioning & Tolerancing

WPI/virtual MA, United States

Geometric Dimensioning and Tolerancing is the universally accepted method of communicating dimensioning requirements on engineering drawings. This workshop will help you understand and use this universal engineering language to communicate the types and amounts of the inevitable variation that parts are allowed to have, per the drawing.

Course Description & Outline

Intended for practicing professionals who create drawing specifications or read drawings, this course helps students make sense of a topic that some find overwhelming. In a safe learning environment, the key principles are explained and brought down to the real world. More than simply memorizing symbols, students leave this course with a working understanding of how the system works and feel confident fully understanding drawing requirements and creating their own tolerancing schemes for parts. This course provides lots of practical hands on exercises to drive home the concepts and encourage questions and effective discussions. The exercises go beyond the theory to show how tolerancing works on real working parts.

- Fundamentals of GD&T: Types of variation and how they’re controlled. Features of size and surfaces. Rule #1. Definitions of maximum material condition (MMC) and least material condition (LMC) and how they are used to determine bonus tolerance.

- Tolerances of Form: Controls of flatness, straightness, circularity and cylindricity. Examples on how they are specified, their meaning and principles of verification. Straightness and flatness controls applied to features of size and surfaces.

- Concept of Datums and the Datum Reference Frame: The common point of reference for the part definition from design through manufacturing and inspection. How imperfect parts are measured according to the design intent.

- Tolerances of Orientation: Controls of parallelism, perpendicularity, and angularity applied to surfaces and features of size. Examples on their use and meaning as well as verification principles.

- Tolerances of Location: Controls of position, comparison and conversion from conventional tolerancing. Applications and examples of position used for various features. Composite position tolerances. The classic examples of floating and fixed fasteners will be cited to demonstrate tolerancing for position to avoid interference problems of fit. Projected tolerance zone. Concentricity and symmetry interpretation and application.

- Tolerances of Profile: Controls of profile of a line and profile of a surface. Equally disposed and unequally disposed profile tolerances. Profile tolerances applied to multiple surfaces. Examples of various simple and complex surfaces.

- Tolerances of Runout: Controls of circular runout and total runout.

Learning Outcomes

- Name the four types of variation that exist on parts, recognize the limitations of numeric tolerances and understand the need for geometric tolerances.

- Analyze tolerances expressed numerically and calculate minimum and maximum allowable values for dimensions.

- Understand and apply the symbols used with the geometric system of tolerances.

- Recognize basic dimensions on prints and understand their meaning.

- Identify and properly read feature control frames.

- Recognize when bonus tolerance is available and calculate geometric tolerance values when bonus tolerance applies.

- Create specifications using bonus tolerance where applicable

- Recognize datum feature identifiers applied to features with size and surfaces.

- Identify the datum reference frame including order of precedence.

- Recognize when datum shift is used and calculate the amount of shift.

- Identify and interpret geometric controls on location, orientation, form, profile & runout.

- Construct illustrations of tolerance zones defined by geometric controls, including 3D and 2D tolerance zones,and those allowed to move.

- Properly evaluate inspection data in light of tolerance zones defined by geometric controls.

Who Should Attend

CAD draftspersons, tool designers, technical inspectors, mechanical engineering, technicians, machine shop and tool room supervisors. Design, manufacturing, and project engineers, quality control personnel, engineering managers and supervisors will also find this workshop beneficial.

For More Information on the Certificate Click Here

Women’s Day: Manufacturing Workshop

SAVE THE DATE 3/29/23

It's Back!

Our 2nd Annual Women's Day Manufacturing Workshop is back to celebrate Women's Day,

and to honor Massachusetts Women in Manufacturing with this workshop.

Join us for a fun late afternoon of panel discussion, networking and hands-on experiences at this year's Women's Day Workshop. Thanks again to our sponsors, Amazon Robotics & WiM for their support and encouragement for women in manufacturing.

Where: Assabet Valley in Marlborough, MA

Time: 4 - 6:30 PM. Registration opens at 4

Who: Women in Manufacturing!!

How: Register Here!

Agenda

4:00 PM Registration Opens

4:15 Welcome

Keynote Speaker - Sarah Baker, COO & Co-founder at Silverside Detectors Inc.

Panel Discussion - Hire Up: moving forward and upward in manufacturing careers

Robin Trickett, CFO Union Machine

Mary May, Director of Assabet Community Education

Karen Coombs, Director, Global Supply Chain, Amazon Robotics

Sarah Baker, COO & Co-founder at Silverside Detectors Inc.

5:15 Breakout Sessions

Networking

Welding Simulator

Welding Demo

Advanced Geometric Dimensioning & Tolerancing

WPI/virtual MA, United StatesEven with an understanding of the fundamentals of GD&T, many professionals still lack the confidence to expertly and deliberately apply geometric tolerancing and perform tolerance stack-up analyses to clearly define their product designs. Like with any language, this deeper understanding is built off the fundamentals.

Program Logistics

- On-Site Delivery: 2 Days (16 Hours)

- Online Delivery: 4x 3.5-hour sessions (14 hours synchronous instruction + asynchronous pre-work / homework)

- Cost: $1,399

- CEUs: 1.4

- Modes of Teaching and Learning: Lecture/discussion, Individual work sessions, Group work sessions, Large print review

- Textbook: GeoTol Pro 2020, TCI

- Workbook (additional for virtual): Advanced GD&T Workbook, WPI

- Instructor: Charles A. GIllis, P.E. (bio)

Course Description & Outline

The Advanced course helps students apply GD&T to achieve the mating and functional requirements of their parts. This course reinforces fundamentals and provides applications-based exercises where students apply what they have learned. Applications exercises and calculations are performed individually and in teams. The use of functional dimensioning and tolerancing schemes and its effect on assemblies is emphasized throughout the course. Students will expand their understanding of the implications of their specifications on function, manufacturing, inspection, and quality. Students are introduced to tolerance stack-ups and how variation accumulates through an assembly. Students will gain experience and confidence selecting the product definition strategy for an assembly by working more advanced application examples with their peers under the guidance of an expert in a classroom setting.

- Basic GD&T Review: Variation and tolerance, drawing requirements, variation in perspective, 3D & Standards for interpretation. Engineering product definition & downstream processes, Bonus Tolerance, Rule #1, exceptions & overrides. Ambiguity, types of variation & tolerances, Unrelated & related AMEs. Unrelated & related MMEs. Datums and degrees of freedom. Establishing datum reference frames including datum feature precedence and datum modifiers. Additional datum applications including secondary datum feature at MMB, tertiary datum feature at MMB, calculating allowable datum feature shift, and applications for datum feature modifiers.

- Advanced Datum Reference Frame Concepts: Moveable datum targets, Two holes as datum feature, Hole and slot as datum feature, coaxial holes as a datum feature, rotational control, simultaneous requirements, customized datum reference frame. Applications and establishment of the correct functional datum reference frame.

- Tolerance Stack-Ups: Geometric controls in tolerance analysis, the tolerance stack-up chain, preliminary tolerance assignment, analysis and assignment methods.

- Profile Control Concepts: Review of profile including composite profile. Advanced concepts such as free state variation, non-rigid parts; non-uniform profile, dynamic profile. Profile verification applications & gage design. Accumulation of variation across profile tolerances.

- Position Control Concepts: Review of composite tolerancing and dual segment position tolerancing, Advanced concepts such as cylindrical tolerance zone, rectangular tolerance zone, spherical tolerance zone, conical tolerance zone, position boundary. Position verification application exercises & gage design. Determining the correct position tolerance.

- Boundaries: Boundaries and their applications in design and tolerance analysis. Determining Inner & outer boundaries for features with and without modifiers using various datum reference frames. Comparison among circular runout, total runout, position, and profile for coaxial control. Applications of various coaxial tolerances. Accumulation of variation between coaxial features.

Learning Outcomes

- Construct the appropriate functional datum reference frames for parts after analyzing the mating requirements.

- Apply datum feature modifiers where appropriate based on analyzing the requirements.

- Specify datum reference frames properly to represent the part's functional requirements, including the use and interpretation of datum shift where appropriate.

- Apply geometric tolerancing to control features and ensure mating requirements are met.

- Combine the effects of different types of variation using the concept of boundaries, calculate boundary sizes and use boundaries properly in stack-up analysis.

- Specify tolerances to ensure multiple mating part relationships between constrained features.

- Perform tolerance stack-up analysis to assign critical tolerances.

- Apply geometric controls and symbols properly to suit the functional requirements.

- Calculate linear, axial and orientation stack-ups using parts toleranced with either numeric or geometric tolerancing

Who Should Attend

Design, manufacturing, and quality engineers and engineering technicians will find this workshop beneficial. Anyone involved with drawing review and anyone looking for a deeper understanding of how to apply geometric tolerancing and perform tolerance analysis will benefit from this course.

Prerequisites & Preparations

At least one Basic GD&T workshop/course is required as a prerequisite. It's essential that individuals understand the underlying principles that the Basic course is focused on teaching. In addition, students should have at least 1 year of on-the-job experience applying GD&T in the development of mechanical specifications.

Advanced Geometric Dimensioning & Tolerancing

WPI/virtual MA, United StatesEven with an understanding of the fundamentals of GD&T, many professionals still lack the confidence to expertly and deliberately apply geometric tolerancing and perform tolerance stack-up analyses to clearly define their product designs. Like with any language, this deeper understanding is built off the fundamentals.

Program Logistics

- On-Site Delivery: 2 Days (16 Hours)

- Online Delivery: 4x 3.5-hour sessions (14 hours synchronous instruction + asynchronous pre-work / homework)

- Cost: $1,399

- CEUs: 1.4

- Modes of Teaching and Learning: Lecture/discussion, Individual work sessions, Group work sessions, Large print review

- Textbook: GeoTol Pro 2020, TCI

- Workbook (additional for virtual): Advanced GD&T Workbook, WPI

- Instructor: Charles A. GIllis, P.E. (bio)

Course Description & Outline

The Advanced course helps students apply GD&T to achieve the mating and functional requirements of their parts. This course reinforces fundamentals and provides applications-based exercises where students apply what they have learned. Applications exercises and calculations are performed individually and in teams. The use of functional dimensioning and tolerancing schemes and its effect on assemblies is emphasized throughout the course. Students will expand their understanding of the implications of their specifications on function, manufacturing, inspection, and quality. Students are introduced to tolerance stack-ups and how variation accumulates through an assembly. Students will gain experience and confidence selecting the product definition strategy for an assembly by working more advanced application examples with their peers under the guidance of an expert in a classroom setting.

- Basic GD&T Review: Variation and tolerance, drawing requirements, variation in perspective, 3D & Standards for interpretation. Engineering product definition & downstream processes, Bonus Tolerance, Rule #1, exceptions & overrides. Ambiguity, types of variation & tolerances, Unrelated & related AMEs. Unrelated & related MMEs. Datums and degrees of freedom. Establishing datum reference frames including datum feature precedence and datum modifiers. Additional datum applications including secondary datum feature at MMB, tertiary datum feature at MMB, calculating allowable datum feature shift, and applications for datum feature modifiers.

- Advanced Datum Reference Frame Concepts: Moveable datum targets, Two holes as datum feature, Hole and slot as datum feature, coaxial holes as a datum feature, rotational control, simultaneous requirements, customized datum reference frame. Applications and establishment of the correct functional datum reference frame.

- Tolerance Stack-Ups: Geometric controls in tolerance analysis, the tolerance stack-up chain, preliminary tolerance assignment, analysis and assignment methods.

- Profile Control Concepts: Review of profile including composite profile. Advanced concepts such as free state variation, non-rigid parts; non-uniform profile, dynamic profile. Profile verification applications & gage design. Accumulation of variation across profile tolerances.

- Position Control Concepts: Review of composite tolerancing and dual segment position tolerancing, Advanced concepts such as cylindrical tolerance zone, rectangular tolerance zone, spherical tolerance zone, conical tolerance zone, position boundary. Position verification application exercises & gage design. Determining the correct position tolerance.

- Boundaries: Boundaries and their applications in design and tolerance analysis. Determining Inner & outer boundaries for features with and without modifiers using various datum reference frames. Comparison among circular runout, total runout, position, and profile for coaxial control. Applications of various coaxial tolerances. Accumulation of variation between coaxial features.

Learning Outcomes

- Construct the appropriate functional datum reference frames for parts after analyzing the mating requirements.

- Apply datum feature modifiers where appropriate based on analyzing the requirements.

- Specify datum reference frames properly to represent the part's functional requirements, including the use and interpretation of datum shift where appropriate.

- Apply geometric tolerancing to control features and ensure mating requirements are met.

- Combine the effects of different types of variation using the concept of boundaries, calculate boundary sizes and use boundaries properly in stack-up analysis.

- Specify tolerances to ensure multiple mating part relationships between constrained features.

- Perform tolerance stack-up analysis to assign critical tolerances.

- Apply geometric controls and symbols properly to suit the functional requirements.

- Calculate linear, axial and orientation stack-ups using parts toleranced with either numeric or geometric tolerancing

Who Should Attend

Design, manufacturing, and quality engineers and engineering technicians will find this workshop beneficial. Anyone involved with drawing review and anyone looking for a deeper understanding of how to apply geometric tolerancing and perform tolerance analysis will benefit from this course.

Prerequisites & Preparations

At least one Basic GD&T workshop/course is required as a prerequisite. It's essential that individuals understand the underlying principles that the Basic course is focused on teaching. In addition, students should have at least 1 year of on-the-job experience applying GD&T in the development of mechanical specifications.

Basic Geometric Dimensioning & Tolerancing

WPI/virtual MA, United States

Geometric Dimensioning and Tolerancing is the universally accepted method of communicating dimensioning requirements on engineering drawings. This workshop will help you understand and use this universal engineering language to communicate the types and amounts of the inevitable variation that parts are allowed to have, per the drawing.

Course Description & Outline

Intended for practicing professionals who create drawing specifications or read drawings, this course helps students make sense of a topic that some find overwhelming. In a safe learning environment, the key principles are explained and brought down to the real world. More than simply memorizing symbols, students leave this course with a working understanding of how the system works and feel confident fully understanding drawing requirements and creating their own tolerancing schemes for parts. This course provides lots of practical hands on exercises to drive home the concepts and encourage questions and effective discussions. The exercises go beyond the theory to show how tolerancing works on real working parts.

- Fundamentals of GD&T: Types of variation and how they’re controlled. Features of size and surfaces. Rule #1. Definitions of maximum material condition (MMC) and least material condition (LMC) and how they are used to determine bonus tolerance.

- Tolerances of Form: Controls of flatness, straightness, circularity and cylindricity. Examples on how they are specified, their meaning and principles of verification. Straightness and flatness controls applied to features of size and surfaces.

- Concept of Datums and the Datum Reference Frame: The common point of reference for the part definition from design through manufacturing and inspection. How imperfect parts are measured according to the design intent.

- Tolerances of Orientation: Controls of parallelism, perpendicularity, and angularity applied to surfaces and features of size. Examples on their use and meaning as well as verification principles.

- Tolerances of Location: Controls of position, comparison and conversion from conventional tolerancing. Applications and examples of position used for various features. Composite position tolerances. The classic examples of floating and fixed fasteners will be cited to demonstrate tolerancing for position to avoid interference problems of fit. Projected tolerance zone. Concentricity and symmetry interpretation and application.

- Tolerances of Profile: Controls of profile of a line and profile of a surface. Equally disposed and unequally disposed profile tolerances. Profile tolerances applied to multiple surfaces. Examples of various simple and complex surfaces.

- Tolerances of Runout: Controls of circular runout and total runout.

Learning Outcomes

- Name the four types of variation that exist on parts, recognize the limitations of numeric tolerances and understand the need for geometric tolerances.

- Analyze tolerances expressed numerically and calculate minimum and maximum allowable values for dimensions.

- Understand and apply the symbols used with the geometric system of tolerances.

- Recognize basic dimensions on prints and understand their meaning.

- Identify and properly read feature control frames.

- Recognize when bonus tolerance is available and calculate geometric tolerance values when bonus tolerance applies.

- Create specifications using bonus tolerance where applicable

- Recognize datum feature identifiers applied to features with size and surfaces.

- Identify the datum reference frame including order of precedence.

- Recognize when datum shift is used and calculate the amount of shift.

- Identify and interpret geometric controls on location, orientation, form, profile & runout.

- Construct illustrations of tolerance zones defined by geometric controls, including 3D and 2D tolerance zones,and those allowed to move.

- Properly evaluate inspection data in light of tolerance zones defined by geometric controls.

Who Should Attend

CAD draftspersons, tool designers, technical inspectors, mechanical engineering, technicians, machine shop and tool room supervisors. Design, manufacturing, and project engineers, quality control personnel, engineering managers and supervisors will also find this workshop beneficial.

For More Information on the Certificate Click Here

CONNEX Massachusetts Registration & Training Session

The session is created for Massachusetts Manufacturers that are interested in joining the CONNEX Supply Chain Database. If you are new to the platform MassMEP representatives will be live to get you registered, walk you through the features of the platform, and answer questions.

Session times and dates are listed in the MassMEP workshop calendar. Click the link on your preferred date to join the live session, no registration necessary. Manufacturers will only need to attend one training session.

Through the MassMEP partnership, a lifetime CONNEX Massachusetts subscription is available at no cost for all Massachusetts Manufacturers. To join the CONNEX Marketplace National Database account holders will receive a promotion code that equates to an annual savings of $500/year. This offer is valid through June 13, 2023.

his work with Dynamic Design Consulting, LLC, he helps clients with product design, design for assemblability and manufacturability, design documentation, tolerance stack-up analysis, and related capability-building. He has invented and designed mechanical and electro-mechanical devices of great diversity, from high-speed, fully-automated precision mechanisms and manufacturing machinery to kinetic sculptures installed as public art.

his work with Dynamic Design Consulting, LLC, he helps clients with product design, design for assemblability and manufacturability, design documentation, tolerance stack-up analysis, and related capability-building. He has invented and designed mechanical and electro-mechanical devices of great diversity, from high-speed, fully-automated precision mechanisms and manufacturing machinery to kinetic sculptures installed as public art.